In search of new alloys for aerospace applications

By Nicola Nosengo - NCCR MARVEL

Finding new materials that can withstand very high temperatures of 1,200 °C and beyond is critical for many industries, such as aircraft engines or nuclear applications. Refractory alloys that include multiple elements from groups 4, 5, and 6 of the periodic table (the titanium, vanadium and chromium groups respectively) are among the most interesting candidates. Precipitation hardening is often used to improve their mechanical properties, and entails heating the alloy to transform it into a mixture of a disordered solid solution with insoluble solids, called precipitates, embedded into it. But controlling the process is challenging, and the first step to do it is to improve its theoretical understanding.

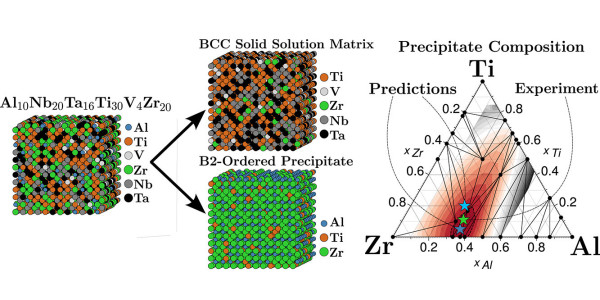

A study by Yann L. Müller, a PhD student in Anirudh Raju Natarajan’s laboratory at EPFL, part of NCCR MARVEL, has used computational methods to accurately describe the properties of a 6-component alloy made of aluminum , niobium, titanium, vanadium, zirconium and tantalum. This material has a very desirable microstructure comprised of a disordered solid solution matrix and embedded precipitates of an ordered phase. “That’s what you want for aircraft applications, because it’s very similar to nickel-based superalloys currently used in aircraft turbines” says Müller, who in his PhD is working to model complex precipitation in high entropy alloys.

“Modelling thermodynamics in such multicomponent systems can be complex as you need to cover a vast compositional space”, he says. “What is interesting in this alloy is that its precipitates are mainly composed of only three elements: aluminum, titanium and zirconium”. So, he thought to use density functional theory (DFT) calculations and cluster expansions to accurately predict the energetics of order-disorder transformations in this complex multicomponent material.

As shown in an article just published in Acta Materialia, predictions from ab-initio calculations are in excellent agreement with experiment. Two things that immediately emerge from DFT data are that all bcc orderings that can form are metastable, at least at 0 K, and that all the ground state precipitates have aluminum segregated to a single sublattice of the conventional bcc cell.

Then Müller used Monte Carlo simulations to go beyond 0 K and found that aluminum segregates to a single sublattice of the conventional bcc cell, even at very high temperatures. But this only holds if aluminum makes up less than 50 per cent of the precipitate. “This confirms what experimentalists have seen, that is that that you only see ordered precipitates with about 20-30 per cent of aluminum” he says. The scientists were also able to compute the composition of the solid solution and precipitate observed in experiment. Predictions from their thermodynamic model is in good agreement with experiment and suggests that the precipitate formed in experiment is metastable.

The study also allowed to derive some design rules for experimentalists on how to improve the performance of the alloy. For example, the calculations suggest that it could be made more thermally stable by increasing the concentrations of aluminium and zirconium or vanadium and tantalum, while simultaneously reducing the niobium content - although increasing the vanadium composition could generate other problems because of the low melting temperature of its oxide. And increasing the concentration of aluminium and zirconium could induce the formation of more complex intermetallic phases.

“Now that we know that our computational model can accurately predict precipitation in complex alloys, we plan to extend our model to a larger compositional space” says Müller. “And we want to search for new alloy compositions that could form ordered precipitates”.

Reference

Yann L. Müller and Anirudh Raju Natarajan, "First-principles thermodynamics of precipitation in aluminum-containing refractory alloys", Acta Materialia, 274, 119995 (2024). https://doi.org/10.1016/j.actamat.2024.119995

Low-volume newsletters, targeted to the scientific and industrial communities.

Subscribe to our newsletter