Theory-guided design identifies single-phase high entropy alloys with appealing properties

By Carey Sargent, EPFL, NCCR MARVEL

Alloying has long been used to tweak the properties of metals and, traditionally, it involves adding relatively small amounts of a secondary element to a primary element. A relatively new strategy, however, involves the combination of five or more elements in near-equal concentrations, creating so-called high-entropy alloys (HEA).

A subset, body-centered cubic (bcc) refractory HEAs, appears to be particularly promising in the search for new high-temperature alloys that can enable higher-efficiency/lower-emissions power generation. These alloys, developed from the Cr-Mo-W-V-Nb-Ta-Ti-Zr-Hf-Al family may allow for a combination of high strength and thermodynamic stability at high temperature with low density and room-temperature ductility. It’s clear, however, that exploring such possible alloys is a huge undertaking: with 10 possible elements, and composition increments of 5%, there are 10 million different possible 5-component alloys. Alloys that satisfy multiple requirements in terms of strength, ductility, thermodynamic stability, and oxidation resistance may exist, but the question is how to find them.

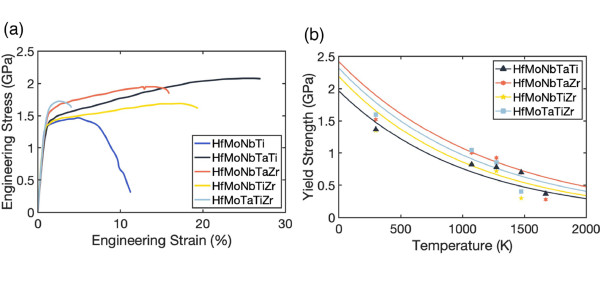

Figure 1. (a) Compressive stress-strain curve at room temperature and (b) predicted yield strength versus temperature (solid lines) in comparison with experiment results (markers) for the equiatomic single phase quinary high entropy alloys.

Indeed, few of the BCC alloys in the Cr-Mo-W-V-Nb-Ta-Ti-Hf-Zr-Al family have been fabricated, characterized or tested—the cost of thorough exploration using only historical data and intuitive knowledge is prohibitively high.

While database and machine learning methods may seem appealing, there is only limited data available to work with, certainly in terms of the amount of data generally relied on in other ML applications. To address this issue, Curtin and colleagues used their very recent theories and expanded thermodynamic tools to introduce a physics-based approach to the discovery of new alloys that might satisfy the required suite of properties. Their approach, which involves validated mechanistic theories that can be simplified to accurate but easily-computable forms, is described in the article “Theory-guided design of high-strength, high-melting point, ductile, low-density, single-phase BCC high entropy alloys,” published earlier this year in Acta Materialia.

In the paper, the search and discovery method is first used to identify a set of equicomposition 5-component alloys that satisfy realistic challenging requirements. Only one alloy emerged as feasible: HfMoNbTaTi. This alloy had been studied in the literature, and the team showed that their method predicts properties that agree with experimental data. They then identified new non-equicomposition alloys that appear to be even more promising.

They chose one alloy identified by the design process—Hf15Mo25Nb20Ta5Ti35—for fabrication, characterization and testing, and were able to show that it is single phase with high room temperature hardness, high melting point, and low density, further confirming their alloy selection strategy. They also identified a further selection of quaternary Hf-Mo- Nb-Ti alloys as promising for future study.

The method is general, and can be adapted to other performance requirements. The theory-guided design process is also easily extendable, providing a reliable, efficient path for the discovery of next-generation high-temperature alloys, the researchers said.

References:

Y. Rao, C. Baruffi, A. De Luca, C. Leinenbach, W.A. Curtin, Theory-guided design of high-strength, high-melting point, ductile, low-density, single-phase BCC high entropy alloys, Acta Materialia, Volume 237, 2022, 118132, ISSN 1359-6454.

Low-volume newsletters, targeted to the scientific and industrial communities.

Subscribe to our newsletter